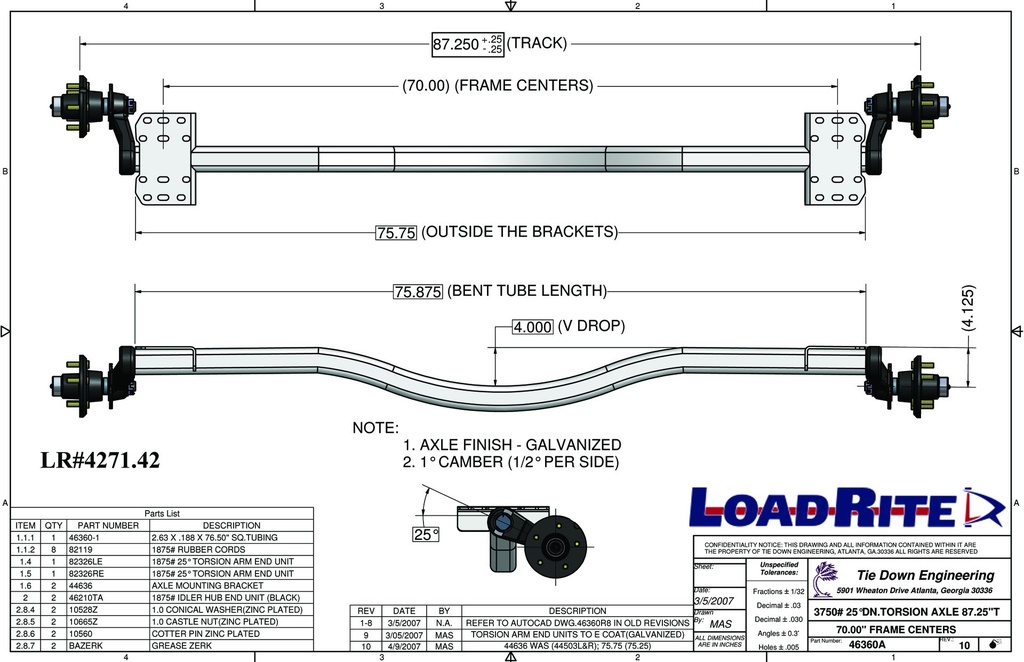

Torsion Axle, 3,700 lb Capacity, 70” Frame Center, 87.5” Hub Face, 75.75” Outside Bracket, 25* Down Angle, Galvanized, Load Rite OEM Axle, Alternate Part #46360A

SKU: 4271.42

Load Rite Galvanized Trailer Torsion Axle With Removable Spindles, 3,700 lbs. Capacity, 87.5" Hub Face, Manufactured by Dexter Marine Products

Details:

Axle Type: Torsion

Notes: Used on Load Rite 96" Tandem Trailers

SuperLube Lubrication

This Axle's Spindle is equipped with Dexter’s SuperLube Lubrication System. The bearings can be periodically lubricated without removing the hubs from the axle. The advantage to this system is that new grease saturates the inner bearing and outer bearing while pushing out the old grease, unlike systems that just push new grease on top of old grease.

1. Remove the rubber plug from the grease (hub) cap.

2. Use a standard grease gun onto the grease fitting located at the end of the spindle, making sure the grease gun nozzle is engaged on the fitting tightly.

3. Pump grease into the fitting, while slowly turning the wheel. Grease will flow out of the hub around the spindle.

4. When the grease appears to be the new clean grease, remove the grease gun and wipe off any excess grease.

5. Replace the rubber plug in the cap.

Details:

Axle Type: Torsion

Weight Capacity: 3,700 lbs

Hub Face (or Track Length): 87.5”

Frame Center: 70”

Outside Bracket: 75.75”

Starting Angle: 25 degree down

Spindle Size: 1-3/8” x 1-1/16”, with SuperLube zerk fitting on the end of the spindles (see details below)

Finish/Material: Galvanized steel

Includes Brake Flange? Yes

Removable Spindles or Trailer Arm? Yes, removable spindles

Includes Hubs? Yes, 5x4.5" bolt pattern

Brand / Manufacturer: Load Rite OEM axle manufactured by Dexter Marine Products

Alternate Part Number(s): 46360ANotes: Used on Load Rite 96" Tandem Trailers

SuperLube Lubrication

This Axle's Spindle is equipped with Dexter’s SuperLube Lubrication System. The bearings can be periodically lubricated without removing the hubs from the axle. The advantage to this system is that new grease saturates the inner bearing and outer bearing while pushing out the old grease, unlike systems that just push new grease on top of old grease.

1. Remove the rubber plug from the grease (hub) cap.

2. Use a standard grease gun onto the grease fitting located at the end of the spindle, making sure the grease gun nozzle is engaged on the fitting tightly.

3. Pump grease into the fitting, while slowly turning the wheel. Grease will flow out of the hub around the spindle.

4. When the grease appears to be the new clean grease, remove the grease gun and wipe off any excess grease.

5. Replace the rubber plug in the cap.

Your Dynamic Snippet will be displayed here...

This message is displayed because youy did not provide both a filter and a template to use.

We're currently collecting product reviews for this item. In the meantime, here are some reviews from our past customers sharing their overall shopping experience.

4.7

Out of 5.0

Overall Rating

95%

of customers that buyfrom this merchant give

them a 4 or 5-Star rating.

April 30, 2024 by J.H. A. (United States)

“Great”

April 30, 2024 by steve S. (United States)

“so far so good quick and easy”

April 29, 2024 by Chris R. (United States)

“Great quick service”